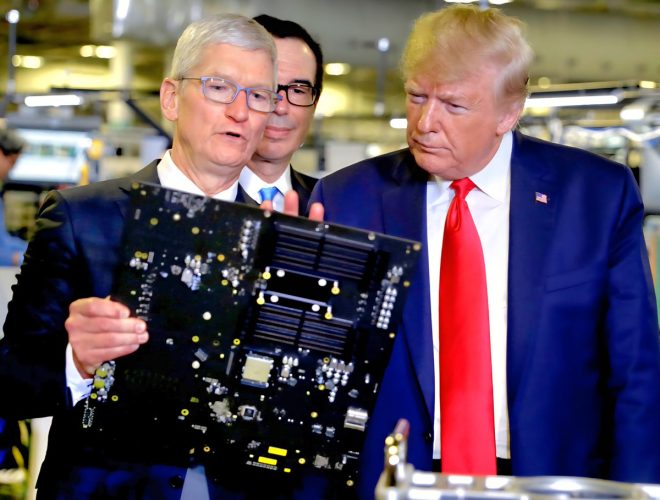

Trump Demands Apple Make iPhones in the US or Face 25% Tariff

In a significant development, former President Donald trump has issued a strong ultimatum to Apple Inc., demanding that the tech giant shift its iPhone manufacturing operations to the United States. This announcement comes amid ongoing discussions about tariffs and trade policies that could impact the global tech industry. Trump’s statement, delivered via social media, emphasizes the importance of domestic manufacturing and aims to bolster American jobs and the economy.

The Context of Trump’s Demands

The backdrop of Trump’s demands can be traced to the ongoing trade tensions between the United States and various countries, particularly China. Over the years, Apple has faced criticism for its reliance on overseas manufacturing, especially in China, where a significant portion of its products are assembled. The reliance on foreign labor has raised concerns about job losses in the U.S. and has been a focal point in Trump’s economic agenda.

Implications of a 25% Tariff

Trump’s warning includes a potential 25% tariff on iPhones imported from overseas if Apple does not comply with his request. Such a tariff could have far-reaching consequences for consumers, Apple, and the tech industry as a whole. A tariff of this magnitude would likely lead to increased prices for consumers, as the additional costs would be passed down the supply chain. This could deter potential buyers and impact Apple’s sales in a competitive market.

Moreover, a shift in manufacturing back to the U.S. would require substantial investment from Apple. The company would need to establish new facilities, hire a skilled workforce, and navigate the regulatory environment. While the prospect of creating American jobs is appealing, the logistical challenges and financial implications cannot be overlooked.

- YOU MAY ALSO LIKE TO WATCH THIS TRENDING STORY ON YOUTUBE. Waverly Hills Hospital's Horror Story: The Most Haunted Room 502

The Economic Impact of Reshoring Manufacturing

Reshoring, or bringing manufacturing back to the U.S., has been a topic of discussion among policymakers and industry leaders for several years. Advocates argue that reshoring can stimulate economic growth, reduce dependency on foreign supply chains, and enhance national security. However, opponents warn that the costs associated with reshoring can be prohibitively high, leading to potential job cuts in the short term as companies adjust to new operational models.

For Apple, a company known for its high profit margins, the decision to reshore could also impact its competitive edge. The tech landscape is characterized by rapid innovation and cost competition, and any increase in production costs could hinder Apple’s ability to maintain its market position.

Consumer Reactions and Market Sentiment

The reaction from consumers and market analysts to Trump’s demands has been mixed. Some consumers express support for the idea of American-made products, citing concerns over labor practices and environmental standards in overseas factories. They argue that manufacturing iPhones in the U.S. could lead to higher quality products and support local economies.

Conversely, many consumers are concerned about the potential rise in prices that could accompany a shift to domestic production. The iPhone is already a premium product, and any increase in price could alienate budget-conscious consumers. Market analysts suggest that a significant price hike could lead to decreased sales and market share for Apple, especially in a landscape where competitors like Samsung and Google are continually innovating and offering alternative options.

The Future of Tech Manufacturing in the U.S.

Trump’s ultimatum to Apple raises broader questions about the future of tech manufacturing in the U.S. As companies navigate the complexities of global supply chains, many are considering ways to balance cost efficiency with domestic production. The COVID-19 pandemic highlighted vulnerabilities in global supply chains, prompting many businesses to rethink their manufacturing strategies.

Some experts predict that more companies may follow Apple’s lead and explore opportunities for reshoring. However, this will likely be a gradual process, as companies weigh the costs and benefits of domestic production against the backdrop of a competitive global market.

Conclusion

Trump’s demands for Apple to manufacture iPhones in the U.S. or face a 25% tariff underscore the growing emphasis on domestic manufacturing and the complexities of global trade. While the push for reshoring may resonate with many consumers and policymakers, the practical implications for Apple and the tech industry as a whole remain uncertain. As discussions continue, the outcome of this demand could shape the future landscape of the American manufacturing sector and influence consumer behavior in the tech market.

In summary, the intersection of politics, economics, and consumer sentiment is at play in this unfolding situation, and stakeholders across the board will be closely monitoring developments. Whether or not Apple will heed Trump’s call remains to be seen, but the conversation about American manufacturing and its implications for the economy is more relevant than ever.

BREAKING: Trump Demands Apple Make iPhones in US or Face 25% Tariff pic.twitter.com/vpIQ6tXFmv

— TaraBull (@TaraBull808) May 23, 2025

BREAKING: Trump Demands Apple Make iPhones in US or Face 25% Tariff

In a bold move that has sent shockwaves through the tech industry, former President Donald Trump has reiterated his demand for Apple to shift its iPhone manufacturing back to the United States. This demand comes with a hefty warning: if Apple does not comply, they could face a staggering 25% tariff on their imports. This statement not only highlights the ongoing tensions between the U.S. and China but also raises critical questions about the future of manufacturing in America and the tech giant’s business strategy.

Why the Demand for Domestic Manufacturing?

Trump’s push for Apple to manufacture iPhones in the U.S. isn’t just a random request. It taps into a broader narrative of American nationalism and economic independence. Over the years, Apple has moved much of its production overseas, primarily to China, where labor costs are significantly lower. By bringing iPhone production back to the U.S., Trump argues that Apple could create jobs and stimulate the local economy.

Moreover, with ongoing global supply chain issues exacerbated by the COVID-19 pandemic, there is a growing sentiment that critical manufacturing should be closer to home. This is not just about jobs; it’s about national security and economic resilience. In a world where supply chains can be disrupted at any moment, having a domestic manufacturing base for essential products like smartphones could be a game-changer.

The Implications of a 25% Tariff

Now, let’s talk about the potential consequences of a 25% tariff on Apple’s imports. If Apple doesn’t comply with Trump’s demands, this tariff would significantly increase the costs of iPhones sold in the U.S. This might lead to higher prices for consumers, which could result in a decline in sales. Apple products are already considered premium items, and adding a hefty tariff could push them out of reach for many average consumers.

Additionally, this situation could trigger a domino effect across the tech industry. Other companies that rely on overseas manufacturing might face similar challenges and pressures. If tariffs become the norm, we could see a shift in how companies approach their manufacturing strategies. Will they start moving production back to the U.S. to avoid tariffs, or will they seek other countries with lower tariffs but similar production capabilities? The answer could reshape the landscape of the tech industry.

The Response from Apple and the Tech Community

As of now, Apple has remained relatively quiet regarding Trump’s latest demands. However, the company has previously expressed its commitment to creating jobs in the U.S. In recent years, Apple has invested in American manufacturing initiatives, such as the creation of the $430 billion investment plan aimed at generating more American jobs and expanding its operations in the U.S.

Nevertheless, shifting iPhone production entirely back to the U.S. is no small feat. The complexities of the supply chain, the availability of skilled labor, and the costs associated with domestic manufacturing are significant hurdles. The tech community is closely observing this situation, as it could create ripples across various sectors, affecting everything from electronics to consumer goods.

The Broader Economic Context

Trump’s demand does not exist in a vacuum. It reflects broader economic trends and sentiments in America. With the rise of protectionism and a focus on “America First” policies, many industries are grappling with how to balance global supply chains with local manufacturing. The tech sector, known for its global approach, is facing increased scrutiny as consumers and politicians alike prioritize domestic job creation.

The conversation around tariffs, manufacturing, and job creation is more relevant than ever. As the U.S. economy continues to recover from the pandemic, the pressure on companies like Apple to contribute to local job growth is intensifying. This demand might resonate with many Americans who are eager to see jobs returning to their communities.

Consumer Reactions

Consumer sentiment is also a vital component of this narrative. Many Americans feel a strong connection to brands that prioritize domestic manufacturing. If Apple were to bring iPhone production back to American soil, it could bolster the company’s image and resonate well with customers who value homegrown products.

However, there’s a catch. If the prices of iPhones increase due to tariffs or the higher costs of domestic manufacturing, consumers might be more reluctant to purchase these products. It creates a complex balancing act for Apple: how do they maintain their brand loyalty while also ensuring their products remain accessible to the average consumer?

The Future of iPhone Manufacturing

So, what does the future hold for iPhone manufacturing? The landscape is shifting, and companies like Apple will need to adapt to the changing dynamics. While Trump’s demands may seem like a challenge, they could also serve as an opportunity for Apple to innovate and explore new manufacturing strategies.

One possibility could be a hybrid approach. Apple might not fully relocate its manufacturing back to the U.S. but could establish some production facilities domestically while maintaining others overseas. This could help mitigate the risks associated with tariffs while still aligning with consumer expectations for domestic job creation.

Conclusion: A Pivotal Moment for Apple and the Tech Industry

Trump’s demand for Apple to relocate iPhone manufacturing back to the U.S. presents a pivotal moment for the tech giant and the entire industry. With the potential for a 25% tariff looming, Apple faces difficult decisions that could impact its bottom line, consumer relationships, and manufacturing strategies for years to come.

As we watch this situation unfold, one thing is clear: the conversation around manufacturing, tariffs, and job creation is far from over. It’s a complex issue that holds the potential to reshape the future of the tech industry and the broader economy.

BREAKING: Trump Demands Apple Make iPhones in US or Face 25% Tariff